November 2022

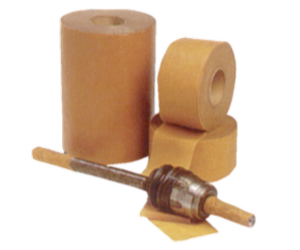

ALSIP, IL (November, 2022) – Pumps, piping, shafts, fluid control equipment and exposed machined surfaces benefit from the corrosion protection of Versil-Pak, a wax-coated barrier wrap manufactured by industry leader Daubert Cromwell.

Originally designed as a waterproof, flexible, wrap for pipelines and equipment buried underground, Versil-Pak has evolved into a full line of product options used to protect oil field machinery, metal tubing, large and irregularly shaped equipment in demanding environments.

Originally designed as a waterproof, flexible, wrap for pipelines and equipment buried underground, Versil-Pak has evolved into a full line of product options used to protect oil field machinery, metal tubing, large and irregularly shaped equipment in demanding environments.

Daubert Cromwell manufactures six types of Versil-Pak, each with excellent dead-fold strength, that are safe and easy to handle: (Daubert_Cromwell_6 Types of Versil-Pak.pdf). Adhesion wax coating works to lock out soil, high moisture, acidity, and corrosion-causing contaminants. Use it as a tight wrap wherever drilling and other types of heavy construction equipment needs strong protection against abrasion and impact.

Durable, high-strength Versil-Pak is standard in 36” wide rolls, 50 and 100 yards long. For military or government applications, ask for Versil-Pak wraps that meet the requirements of Mil-PRF-121, or any of Daubert Cromwell’s other approved papers, films, corrosion inhibitor devices and rust preventive liquids.

Durable, high-strength Versil-Pak is standard in 36” wide rolls, 50 and 100 yards long. For military or government applications, ask for Versil-Pak wraps that meet the requirements of Mil-PRF-121, or any of Daubert Cromwell’s other approved papers, films, corrosion inhibitor devices and rust preventive liquids.

About Daubert Cromwell

Since the 1940’s, Daubert Cromwell has set the standard for corrosion preventive packaging in industry. Its VCI films, papers, liquids, emitters and specialty products are used worldwide to protect metal and metal parts in automotive, electronics, military, aerospace, heavy equipment and energy industries. For more information or to view the company’s range of VCI products, call 800-535-3535 or visit www.daubertcromwell.com.

Alsip, IL - Daubert Cromwell, a global manufacturer of corrosion inhibitors and protective packaging for industry, announces Polly Huang as Director – Asia Sales, Marketing & Business Development. With 13 years of company sales and management experience, Polly now has responsibility for growing the overall line of proprietary VCI packaging and rust preventive liquids business in Asia.

Alsip, IL - Daubert Cromwell, a global manufacturer of corrosion inhibitors and protective packaging for industry, announces Polly Huang as Director – Asia Sales, Marketing & Business Development. With 13 years of company sales and management experience, Polly now has responsibility for growing the overall line of proprietary VCI packaging and rust preventive liquids business in Asia.