July 2024

Alsip, IL – When sensitive electronics need protection from corrosion and electrostatic discharge, manufacturers package them in Daubert Cromwell’s VCI/ESD poly film and bags. Safe, effective Premium Metal-Guard® VCI/ESD is corrosion inhibitor film with static dissipative properties to prevent damage on components commonly used in aerospace, automotive, and other fabricated metals markets.

Alsip, IL – When sensitive electronics need protection from corrosion and electrostatic discharge, manufacturers package them in Daubert Cromwell’s VCI/ESD poly film and bags. Safe, effective Premium Metal-Guard® VCI/ESD is corrosion inhibitor film with static dissipative properties to prevent damage on components commonly used in aerospace, automotive, and other fabricated metals markets.

Flexible, durable, heat-sealable Premium Metal-Guard VCI/ESD works as a barrier to harmful effects of moisture and humidity. It has no effect on solderability. Corrosion protection lasts up to 2 years on steel, brass, copper, stainless steel, and similar metals.

The ESD protection is efficient at relatively low humidity (~15% RH). Odorless, non-toxic and completely recyclable, the film passes resistivity testing and meets all industry standards recognized in the US and Europe -- RoHS, Prop 65, TL-8135, TRGS 615, and TRGS 900.

Parts stay protected until removed from the packaging and put into use. No further cleaning is required.

Parts stay protected until removed from the packaging and put into use. No further cleaning is required.

Film is available in blue, orange, and custom colors; as sheeting, bags, covers, and custom constructions. Ideal for protecting communications equipment, precision machined parts, and static-sensitive devices.

For more about the complete range of corrosion inhibitor products from Daubert Cromwell, call 800-535-3535, +1-708-293-7750; info@daubertcromwell.com

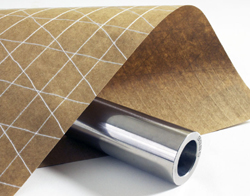

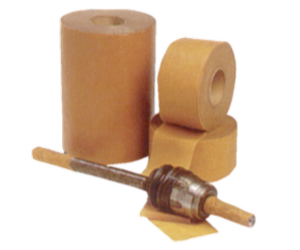

Originally designed as a waterproof, flexible, wrap for pipelines and equipment buried underground,

Originally designed as a waterproof, flexible, wrap for pipelines and equipment buried underground,  Durable, high-strength Versil-Pak is standard in 36” wide rolls, 50 and 100 yards long. For military or government applications, ask for Versil-Pak wraps that meet the requirements of Mil-PRF-121, or any of Daubert Cromwell’s other approved papers, films, corrosion inhibitor devices and rust preventive liquids.

Durable, high-strength Versil-Pak is standard in 36” wide rolls, 50 and 100 yards long. For military or government applications, ask for Versil-Pak wraps that meet the requirements of Mil-PRF-121, or any of Daubert Cromwell’s other approved papers, films, corrosion inhibitor devices and rust preventive liquids.