July 2020

For Immediate Release

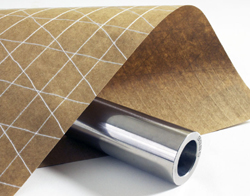

July, 2020 -- Daubert Cromwell has expanded its selection of anti-corrosion packaging for military and industrial commercial uses with a VCI-treated bore tube that protects barrels, spares, shafts and cylindrical shapes. The spirally-wound bore tube is constructed with Daubert Cromwell's VCI paper that is qualified to U.S. Dept. of Defense to Mil-PRF-3420. The VCI tubes, most popular in 19" lengths, are designed to prevent rust inside firearms, hollow tubing, piping, and hard-to-reach narrow spaces.

Each Nox-Rust VCI bore tube is spirally wound with military grade paper that delivers safe, non-toxic, effective rust protection to steel, cast iron and ferrous alloy surfaces. The protection is dry, clean, and eliminates the need to apply oils or liquids. When the tubing is removed, the part is ready to use without need for further cleaning or rework. Tubes are fully recyclable and repulpable.

To use, place a VCI bore tube into the length of a clean, dry cylinder shape up to 1" diameter. Close off both ends to maintain the packaging environment. The corrosion protection will last up to 24 months in proper storage conditions.

For metal parts of ferrous/non-ferrous combinations, fabricators often choose to package finished components in military-listed Premium Metal-Guard VCI film for added barrier protection. The VCI poly film is available in bag sizes small enough to contain trigger assemblies, and large enough to cover entire units aboard ships.

For complete information about corrosion inhibitor packaging for military and commercial applications, call at 800-535-3535; +1-708-293-7750; or email info@daubertcromwell.com